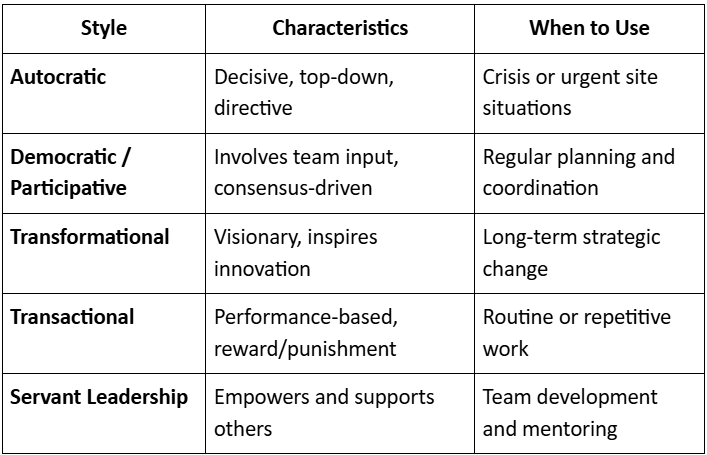

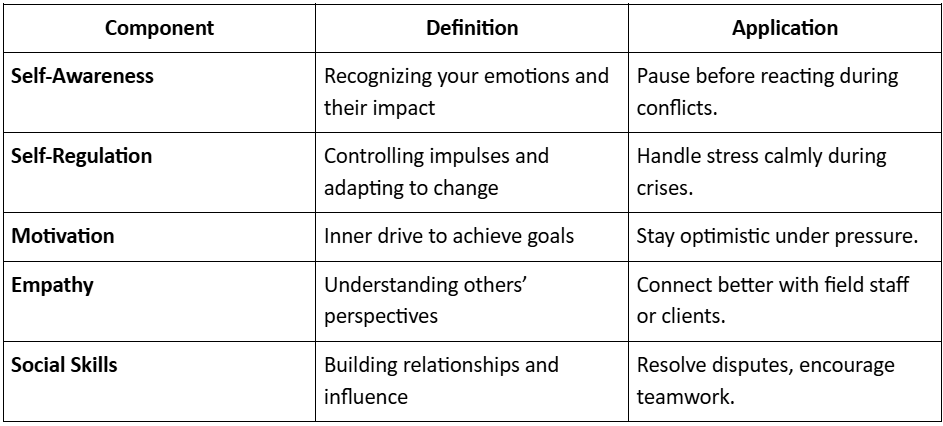

Creating a quality culture requires leadership commitment, teamwork, and empowerment at all levels.

1. Building a Quality-Driven Organization

- Leadership Commitment: Management must visibly support quality goals.

- Empowered Employees: Encourage workers to stop work if they notice quality risks.

- Recognition Programs: Reward zero-defect teams and quality improvements.

- Integrated Communication: Display KPIs, quality dashboards, and safety boards on-site.

- Cross-Functional Reviews: Bring together design, QA, and execution teams for joint analysis.

2. Institutionalizing Quality

- Adopt ISO 9001:2015 Quality Management System (QMS) standards.

- Embed quality checkpoints into project scheduling and WBS.

- Conduct monthly TQM review meetings with management.

- Integrate TQM KPIs into performance appraisals and vendor evaluations.

3. Sustaining the Culture

- Share success stories and lessons learned across teams.

- Maintain open communication on defects — no blame culture.

- Continuously improve through audits, client feedback, and benchmarking.

Module Summary

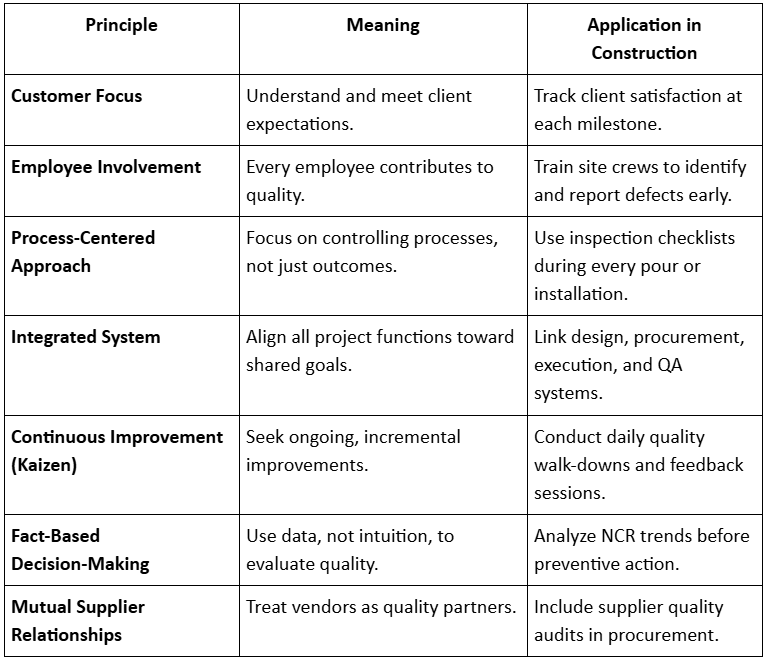

- TQM emphasizes customer satisfaction, teamwork, and process excellence.

- Continuous improvement through PDCA and benchmarking enhances performance.

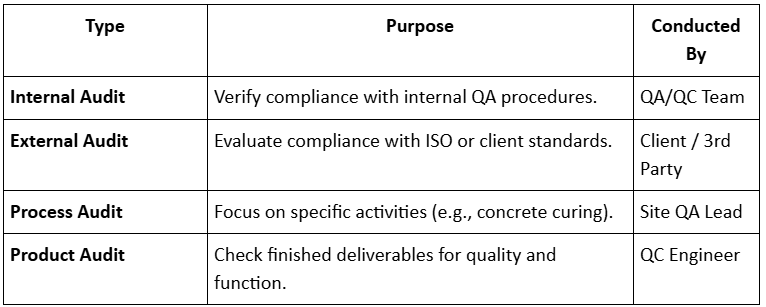

- Audits and training ensure compliance and awareness at all levels.

- 7QC tools provide data-driven insight into quality issues.

A strong quality culture sustains performance and client trust across projects.